Industry 4.0 is steadily reshaping many manufacturing sectors, and fan manufacturing is no exception. This new wave of industrial transformation integrates digital technologies such as the Internet of Things (IoT), automation, data analytics, and smart manufacturing processes. These advances are influencing how fans, including axial duct fans, large industrial wall mounted fans, and small commercial ceiling fans, are designed, produced, and maintained.

One notable impact of Industry 4.0 on fan manufacturing is in the area of production efficiency. Traditional fan manufacturing often involved labor-intensive processes, manual assembly, and limited real-time monitoring. Now, smart factories equipped with interconnected machines allow for streamlined workflows and continuous data feedback. For example, automated machining centers can precisely cut and shape components for axial duct fans with reduced errors and faster turnaround times. Sensors embedded throughout the production line provide instant insights into equipment status and product quality, helping manufacturers address issues before they cause delays.

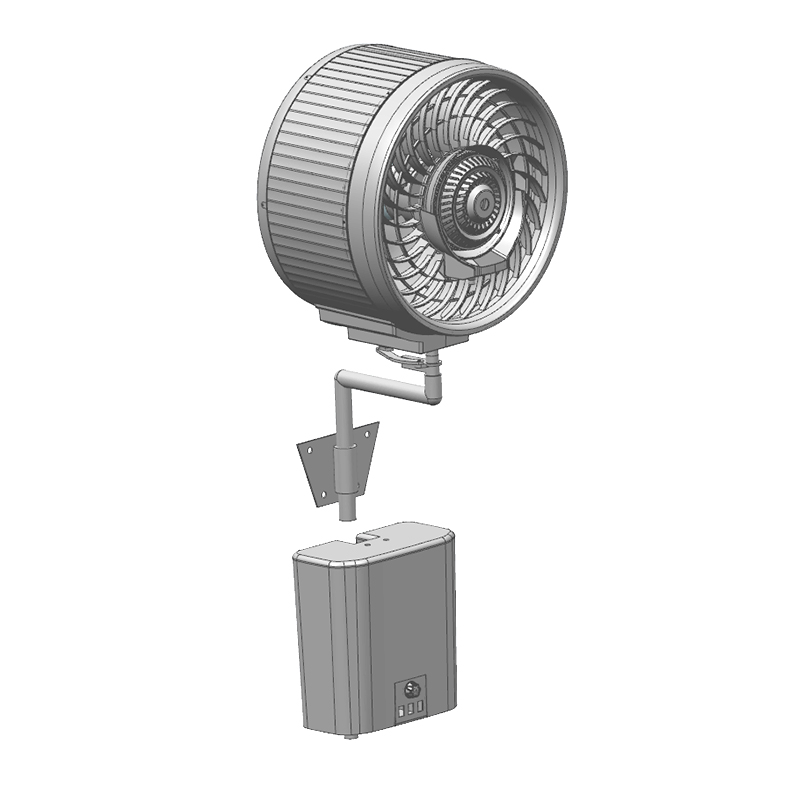

Another significant development is customization. Market demands are shifting toward fans tailored to specific environments and requirements. With digital design tools and advanced manufacturing methods like 3D printing and flexible CNC machining, manufacturers can offer more adaptable fan solutions. Small commercial ceiling fans, for instance, can be designed with variable blade angles or integrated smart controls to suit different room sizes and airflow needs. Similarly, large industrial wall-mounted fans benefit from modular designs that allow for easy adjustments or upgrades based on customer feedback or changing site conditions.

Data analytics and predictive maintenance also play a critical role in the Industry 4.0 era. Fans used in industrial or commercial settings are often subject to continuous operation, making reliability essential. By outfitting fans such as axial duct fans with sensors to monitor vibration, temperature, and motor performance, manufacturers and end-users can collect valuable data. This information can be analyzed to predict potential failures or maintenance needs, less downtime, and extended product life. Predictive maintenance reduces unexpected breakdowns, which is especially important in large-scale applications where fan failure could disrupt entire ventilation systems.

The integration of IoT technologies further enhances fan operation and monitoring. Smart fans connected to cloud platforms allow facility managers to remotely monitor and control ventilation systems. This capability is especially useful for large industrial wall mounted fans, which may serve vast warehouse or manufacturing spaces. Real-time adjustments can optimize airflow to match environmental conditions, improving energy efficiency and comfort. For commercial settings, small ceiling fans equipped with wireless controls offer users convenience and adaptability, such as adjusting speed or activating timers from a smartphone app.

Sustainability is another area influenced by Industry 4.0 advancements. Efficient production methods and smarter fan designs contribute to reduced energy consumption during manufacturing and fan operation. Digital simulations help engineers optimize blade shapes and motor performance before physical prototypes are built, reducing material waste. Additionally, smart control systems ensure fans run only when needed and at appropriate speeds, lowering electricity usage. This attention to sustainability aligns with growing environmental awareness and regulatory requirements in many regions.

While the benefits of Industry 4.0 in fan manufacturing are clear, the transition requires investments in technology and workforce training. Manufacturers are increasingly investing in digital infrastructure and upskilling their teams to effectively utilize new tools and systems. Collaboration between engineers, data scientists, and production staff helps create a seamless workflow from design to delivery. Over time, this integrated approach fosters innovation and responsiveness in a competitive market.

Add: Plot 23, Huanglang Industrial Zone, Jinqing Town, Luqiao District, Taizhou City, Zhejiang Province

Add: Plot 23, Huanglang Industrial Zone, Jinqing Town, Luqiao District, Taizhou City, Zhejiang Province

TEL: +86-13586083215

TEL: +86-13586083215

English

English English

English عربى

عربى 한국어

한국어